Understanding and diagnosing fuel injection systems can seem like a daunting task, but it doesn’t have to be. With the right tools and techniques, you can diagnose problems efficiently and effectively. In this blog, we will explore some of the best tools and techniques for diagnosing issues in fuel injection systems. This guide aims to be simple, readable, and easy to understand for everyone.

ADDITIONALLY : Discover top-notch Fuel Injection Parts and Services in UAE. Enhance your vehicle’s efficiency and reliability with our premium solutions. Contact us now to schedule an appointment or learn more about our specialized services. Don’t wait – fuel your drive with excellence!

Understanding Fuel Injection Systems

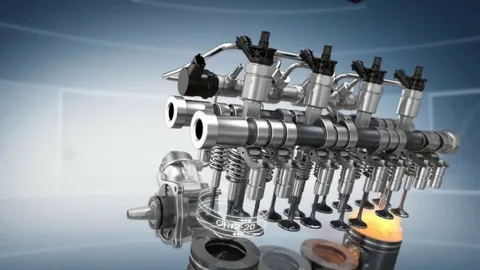

Fuel injection systems are a crucial part of modern vehicles. They are responsible for delivering the right amount of fuel to the engine cylinders, ensuring optimal performance and efficiency. Unlike older carburetor systems, fuel injection systems are more precise and can adapt to different driving conditions. They play a significant role in reducing emissions and improving fuel economy. Understanding how these systems work is the first step in diagnosing any issues that may arise.

Fuel injection systems work by spraying fuel directly into the engine’s combustion chambers. This is done using injectors, which are controlled by the vehicle’s engine control unit (ECU). The ECU calculates the amount of fuel needed based on various factors, such as engine temperature, air intake, and throttle position. This precise control allows for better performance and efficiency. However, when something goes wrong, it can be challenging to pinpoint the exact issue without the proper tools and techniques.

Common Problems with Fuel Injection Systems

Before diving into the tools and techniques, it’s essential to know some of the common problems that can occur with fuel injection systems. These issues can range from minor glitches to major failures, and recognizing the symptoms early can save you a lot of time and money. Some common problems include clogged injectors, faulty sensors, and issues with the fuel pump. Each of these problems can cause various symptoms, such as rough idling, poor fuel economy, and reduced engine performance.

Clogged injectors are one of the most common issues with fuel injection systems. Over time, dirt and debris can build up in the injectors, causing them to become clogged. This can lead to poor fuel delivery and reduced engine performance. Faulty sensors, such as the oxygen sensor or mass air flow sensor, can also cause problems. These sensors provide crucial information to the ECU, and if they are not working correctly, it can lead to incorrect fuel delivery. Issues with the fuel pump can also cause problems. The fuel pump is responsible for delivering fuel from the tank to the injectors, and if it is not working correctly, it can lead to a lack of fuel delivery.

Essential Tools for Fuel Injection System Diagnostics

Having the right tools is essential for diagnosing fuel injection system problems. There are several tools that every mechanic or car enthusiast should have in their toolbox. These tools will help you diagnose and fix problems quickly and efficiently. Some essential tools include a fuel pressure gauge, an OBD-II scanner, and a digital multimeter. Each of these tools has a specific purpose and can help you diagnose different aspects of the fuel injection system.

A fuel pressure gauge is a crucial tool for diagnosing fuel injection system problems. It allows you to measure the fuel pressure in the system, which can help you identify issues with the fuel pump or fuel pressure regulator. An OBD-II scanner is another essential tool. This scanner can read the trouble codes stored in the ECU, which can help you identify faulty sensors or other issues. A digital multimeter is also a must-have tool. It allows you to measure voltage, resistance, and continuity, which can help you diagnose electrical issues in the fuel injection system.

Techniques for Diagnosing Fuel Injection System Problems

Now that we have covered the essential tools, let’s dive into some techniques for diagnosing fuel injection system problems. These techniques will help you identify and fix issues quickly and efficiently. Some common techniques include checking the fuel pressure, using the OBD-II scanner to read trouble codes, and testing the injectors with a digital multimeter.

Checking the fuel pressure is one of the first steps in diagnosing fuel injection system problems. This can help you identify issues with the fuel pump or fuel pressure regulator. To check the fuel pressure, you will need a fuel pressure gauge. Connect the gauge to the fuel rail and turn on the ignition. The gauge should read within the manufacturer’s specified range. If the pressure is too low, it could indicate a problem with the fuel pump or fuel pressure regulator.

Using an OBD-II scanner to read trouble codes is another crucial technique. This scanner can read the trouble codes stored in the ECU, which can help you identify faulty sensors or other issues. To use the scanner, connect it to the vehicle’s OBD-II port and turn on the ignition. The scanner will display the trouble codes, which you can then look up to identify the issue. This can help you pinpoint the problem quickly and efficiently.

Testing the injectors with a digital multimeter is another essential technique. This can help you identify issues with the injectors, such as clogs or electrical problems. To test the injectors, disconnect the electrical connectors from the injectors and set the multimeter to measure resistance. Measure the resistance of each injector and compare it to the manufacturer’s specifications. If the resistance is too high or too low, it could indicate a problem with the injector.

Preventive Maintenance for Fuel Injection Systems

Preventive maintenance is crucial for keeping your fuel injection system in good working order. Regular maintenance can help prevent issues before they become major problems. Some preventive maintenance tips include using high-quality fuel, regularly cleaning the injectors, and replacing the fuel filter. These simple steps can help ensure that your fuel injection system stays in good working order.

Using high-quality fuel is one of the easiest ways to prevent problems with your fuel injection system. High-quality fuel contains fewer impurities, which can help prevent clogs in the injectors. Regularly cleaning the injectors is another important step. There are several injector cleaning products available that can help remove dirt and debris from the injectors. Replacing the fuel filter is also crucial. The fuel filter helps remove impurities from the fuel before it reaches the injectors, and a clogged filter can cause problems with fuel delivery.

Conclusion

In conclusion, diagnosing fuel injection system problems doesn’t have to be complicated. With the right tools and techniques, you can identify and fix issues quickly and efficiently. Understanding how the fuel injection system works and recognizing common problems is the first step. Having essential tools like a fuel pressure gauge, OBD-II scanner, and digital multimeter is crucial. Using techniques like checking the fuel pressure, reading trouble codes, and testing the injectors can help you diagnose issues. Preventive maintenance, such as using high-quality fuel, cleaning the injectors, and replacing the fuel filter, can help keep your fuel injection system in good working order. By following these tips, you can ensure that your vehicle runs smoothly and efficiently.

For more insightful articles related to this topic, feel free to visit technotreats