Fire curtains are essential components in building safety systems. They provide critical protection in case of fire, helping to prevent the spread of flames and smoke. But how do fire curtain manufacturers ensure that their products are up to the mark in terms of safety and quality? In this blog, we will explore the processes and standards that fire curtain manufacturers, especially in the UAE, follow to ensure their products are reliable and effective.

NOTE: If you are looking for reliable and certified fire curtain solutions, contact the top Fire Curtain Manufacturers in UAE today to ensure the safety and quality of your building’s fire protection system.

Understanding Fire Curtains

What Are Fire Curtains?

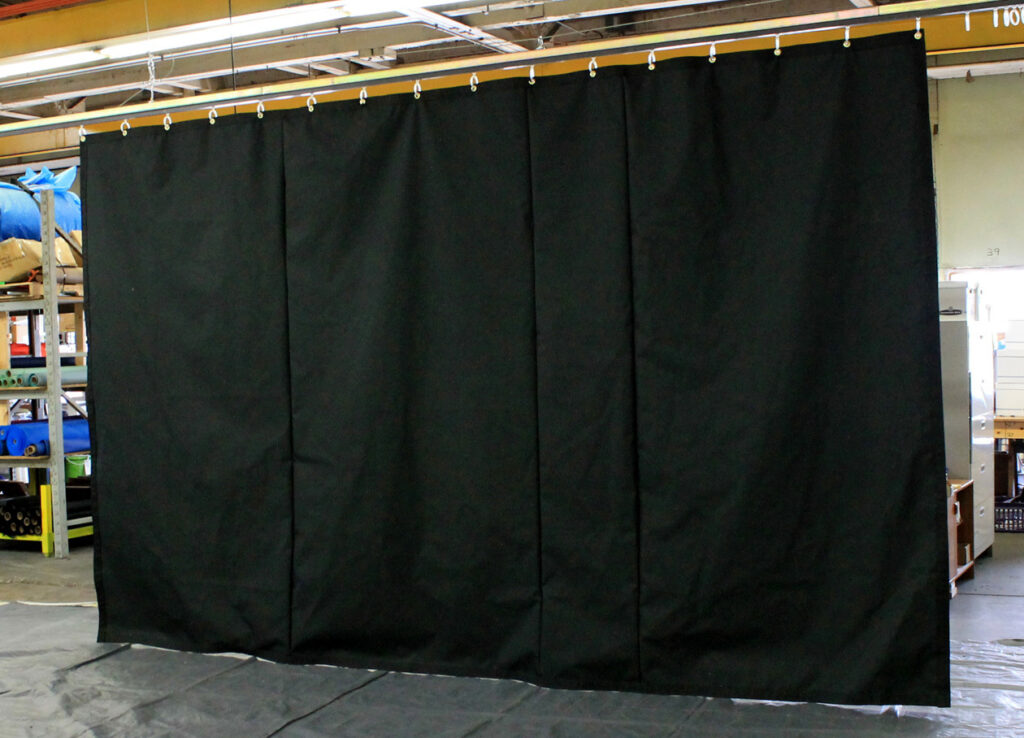

Fire curtains are barriers that automatically deploy in the event of a fire to contain it and protect escape routes. They are typically made of fire-resistant materials and are integrated into a building’s fire safety system.

Why Are Fire Curtains Important?

Fire curtains play a crucial role in maintaining the integrity of fire compartments within buildings. They help to:

- Prevent the spread of fire and smoke.

- Protect escape routes, allowing people to evacuate safely.

- Minimize property damage.

- Comply with fire safety regulations.

Manufacturing Standards and Certifications

International Standards for Fire Curtains

Fire curtain manufacturers adhere to international standards to ensure the safety and quality of their products. These standards include:

- EN 12101-1: Specifies the requirements for smoke barriers.

- BS 8524-1: Details the requirements for active fire curtain barrier assemblies.

- UL 10D: A North American standard for fire protective curtains.

Compliance with Local Regulations

In addition to international standards, manufacturers in the UAE must comply with local fire safety regulations. This ensures that the fire curtains are suitable for use in the specific environmental and building conditions found in the region.

Quality Control Processes

Rigorous Testing Procedures

Fire curtain manufacturers implement rigorous testing procedures to ensure their products meet safety standards. These tests include:

- Fire Resistance Testing: Fire curtains are exposed to high temperatures to verify their ability to withstand fire for a specified period.

- Smoke Control Testing: Ensures that the curtain effectively prevents the passage of smoke.

- Durability Testing: Assesses the curtain’s ability to perform over time and through repeated cycles of deployment and retraction.

Third-Party Certification

To further ensure quality, many manufacturers seek third-party certification from recognized testing laboratories. This certification provides an additional layer of assurance that the fire curtains meet or exceed safety standards.

Materials and Manufacturing Techniques

High-Quality Materials

The effectiveness of a fire curtain largely depends on the materials used in its construction. Manufacturers use high-quality, fire-resistant fabrics such as:

- Fiberglass: Known for its excellent fire resistance and durability.

- Ceramic Fiber: Offers high-temperature resistance.

- Stainless Steel Mesh: Provides structural integrity and fire resistance.

Advanced Manufacturing Techniques

Manufacturers employ advanced manufacturing techniques to produce fire curtains. These techniques ensure precision and consistency, which are critical for the reliable performance of fire curtains. Some of these techniques include:

- Automated Cutting and Sewing: Ensures accurate dimensions and strong seams.

- Heat Sealing: Provides additional strength to the seams and prevents fraying.

- Quality Inspections: Regular inspections throughout the manufacturing process to detect and correct any defects.

Installation and Maintenance

Professional Installation

Proper installation is crucial for the effective performance of fire curtains. Manufacturers often provide detailed installation guidelines or offer professional installation services. This ensures that the curtains are installed correctly and will function as intended in the event of a fire.

Regular Maintenance

Fire curtains require regular maintenance to ensure they remain in good working condition. Manufacturers typically recommend:

- Regular Inspections: To check for wear and tear or any damage.

- Testing: Periodic testing to ensure the curtains deploy and retract properly.

- Repairs and Replacements: Promptly addressing any issues to maintain the integrity of the fire curtain system.

Innovation and Continuous Improvement

Research and Development

Leading fire curtain manufacturers invest in research and development to improve their products continually. This includes:

- Developing New Materials: Finding more effective and durable fire-resistant materials.

- Enhancing Performance: Improving the fire and smoke resistance capabilities of fire curtains.

- Integrating Technology: Using smart technologies to enhance the functionality and monitoring of fire curtain systems.

Feedback and Adaptation

Manufacturers also rely on feedback from customers and fire safety professionals to refine their products. This feedback helps identify areas for improvement and ensures that fire curtains meet the evolving needs of building safety.

Choosing the Right Fire Curtain Manufacturer

Reputation and Experience

When selecting a fire curtain manufacturer, it’s important to consider their reputation and experience. Look for manufacturers with a proven track record of producing high-quality fire curtains and providing excellent customer service.

Certification and Compliance

Ensure that the manufacturer’s products are certified by recognized testing laboratories and comply with both international and local fire safety standards. This is especially important for Fire Curtain Manufacturers in UAE, where adherence to specific regulations is crucial.

Customer Support

Choose a manufacturer that offers comprehensive customer support, including installation guidance, maintenance services, and technical assistance. This ensures that you have the support you need to maintain your fire curtain system effectively.

Conclusion

Fire curtain manufacturers play a critical role in building safety. Through rigorous testing, high-quality materials, advanced manufacturing techniques, and continuous improvement, they ensure that their products provide reliable protection in the event of a fire. When choosing a fire curtain manufacturer, consider their reputation, certification, and customer support to ensure you get the best possible protection for your building.

For more insightful articles related to this topic, feel free to visit technotreats